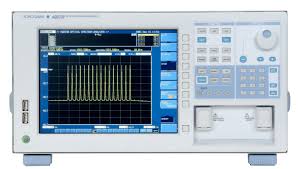

When an Optical Spectrum Analyzer (OSA) slips out of spec—wavelength offset, power drift, failing RBW filters—your pass/fail limits, DWDM channel plans, and insertion-loss budgets stop being trustworthy. Aumictech restores Ando and Yokogawa OSAs to reliable, repeatable performance with NIST-traceable wavelength and power calibration, full optical/mechanical alignment, and a clear before/after report so your audits fly through.

Models we service

Ando

- AQ6310 series: AQ6310 / AQ6310A / AQ6310B / AQ6310C

- AQ6312 series: AQ6312B (600–1700 nm)

- AQ6315 series: AQ6315A / AQ6315E (350–1750 nm)

Yokogawa

- AQ6370 family: AQ6370, AQ6370B/C/D/E (1200–1700 nm variants)

- AQ6373 family: AQ6373B/C/E (visible–NIR)

- AQ6374: extended range 350–1750 nm

- AQ6375/AQ6375B: 1200–2400 nm

- AQ6376 / AQ6377: SWIR 1500–3400 nm (model-dependent)

Don’t see yours? Email sales@aumictech.com with the model and a photo of the front panel.

Get a quick quote here

Symptoms we fix (and what’s behind them)

- Wavelength offset / failed line checks → grating encoder drift, reference source aging, interferometer/monochromator misalignment

- Power level inaccuracy / poor linearity → input optics contamination, attenuator wear, detector gain drift, PSU ripple

- Resolution bandwidth (RBW) failures → slit mechanism wear, filter wheel stiction, mis-zeroed RBW tables

- High noise floor / stray light → internal scatter from dusty optics, degraded baffles, fan/airflow issues

- Sweep glitches / missed points → stepper motor/belt wear, encoder errors, aging capstan grease

- I/O & UI faults → dead keys/knob, dim backlight, unstable fans, intermittent GPIB/USB/LAN

Our repair & calibration workflow

- Intake diagnostics

Record firmware/options, error logs, sweep reproducibility, noise floor, RBW verification, and initial wavelength/power checks. - Optical path restoration

Clean and inspect the input connector, collimation optics, slit assembly, mirrors, and grating under a stereo scope. Replace worn belts, re-lube rails, verify encoder indexing. - Electronics & PSU service

Verify detector bias/gain, PSU ripple/noise, fan performance, NVRAM backup battery, front-panel/knob/keys, display backlight/inverter. - Monochromator alignment

Center/focus on reference beam, set grating angle zero, check slit parallelism and image height for consistent RBW. - NIST-traceable calibration

- Wavelength accuracy & repeatability using reference lasers/line sources positioned across the instrument’s range (e.g., 1310/1550/1625 nm for telecom; visible lines for AQ6315/AQ6373).

- Power accuracy & linearity referenced to NIST-traceable standards across typical levels (e.g., −60 to 0 dBm model-dependent).

- RBW characterization at key settings (e.g., 0.02/0.07/0.2/1.0 nm or model equivalents), verifying 3 dB bandwidth and shape factor.

- Dynamic range & stray-light check via narrow-line tests and out-of-band suppression.

- Functional verification & stress

Long sweeps at multiple spans/resolutions, repeatability across temperature, sweep speed and data integrity tests (CSV/SCPI). - Documentation & return

You receive an as-found / as-left report, NIST-traceable certificate, plots of wavelength/power/RBW checks, and maintenance notes tailored to your model and use case.

Typical repairs we perform

- Input connector ferrule/adapter replacement and optical re-centering

- Slit/attenuator mechanism overhaul (stiction/backlash fixes)

- Grating/encoder realignment and belt replacement

- Detector board front-end re-bias (where applicable)

- PSU recap for stability; fan replacement/noise mitigation

- Front panel key/knob repair and display/backlight service

- I/O port reliability fixes (GPIB/USB/LAN)

How we verify “measurement you can trust”

- Wavelength: multi-point span (short/mid/long), bidirectional sweep agreement, thermal drift profile

- Power: absolute accuracy at selected λ, level linearity vs. input, repeatability over 24-hour dwell

- RBW: 3 dB width & shape factor against narrow-linewidth sources; consistency across ranges

- Noise floor & stray light: out-of-band suppression quantified at standard offsets

- Data integrity: SCPI/CSV export validation for lab systems and manufacturing SPC

Turnaround & shipping

- Evaluation: 1–2 business days after arrival

- Repairs: typically 5–10 business days after approval (parts availability may affect lead time)

- Shipping: nationwide mail-in from Downingtown, PA with protective return packing

Tip: Ship with a dust cap, lock any transport screws if present, and include your fiber jumper so we can validate your exact setup.

What you get back

- OSA restored to stable, repeatable performance for its model class

- NIST-traceable wavelength & power certificate (as-found/as-left)

- Final plots and CSV data for your records/quality system

- Model-specific preventive maintenance plan

Preventive maintenance for longer in-spec time

- Keep the input connector pristine (dust cap on, inspect ferrules before every session)

- Purge dust paths: don’t block intake/exhaust; replace filters as needed

- Warm-up fully before critical measurements (follow model guidance)

- Validate with a quick line/power check weekly; log results for trend spotting

- Avoid over-range light levels; use the OSA’s built-in attenuator or external attenuator

FAQs

Do you calibrate across the full wavelength range of my OSA?

We calibrate at multiple wavelengths spanning your model’s range and verify intermediate points through sweep tests, then document the traceability chain.

Can you fix RBW issues (tests failing at 0.02/0.07/0.2/1.0 nm)?

Yes. We service slit/filter mechanisms, re-index tables, and verify RBW shape and 3 dB width with narrow-line sources.

What if my power reading is consistently high/low by ~0.2 dB?

We clean/realign input optics, verify detector linearity and attenuator accuracy, and recalibrate against NIST-traceable standards.

Do you support SWIR models (AQ6376/6377)?

Yes—support depends on parts availability. Email sales@aumictech.com with your model/serial for a quick confirmation.

Will I get as-found data for audits?

Absolutely. Your report includes as-found and as-left values, environmental conditions, references used, and plots.

Ready to schedule service?

Email sales@aumictech.com with your model, serial, symptoms, and any recent screenshots/plots. We’ll reply with intake steps and a prepaid-label option.