Introduction: The Legacy and Power of Fujikura PM Fusion Splicers

submit a quote today: here

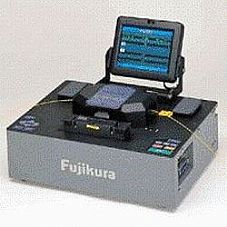

Fujikura has long been recognized as a global leader in optical fusion splicing. From early-generation splicers like the FSM-20PM to the advanced FSM-100P, Fujikura has set industry benchmarks in polarization-maintaining (PM) fiber splicing. These tools are widely used across telecommunications, military systems, photonics R&D, sensor manufacturing, and laser technology sectors.

Due to their precision, complexity, and age (in some models), these splicers require expert service and periodic recalibration to maintain reliable performance. At Aumictech, we offer specialized repair, refurbishment, and NIST-traceable calibration services for all major Fujikura PM fusion splicer models — including the FSM-20PM, FSM-40PM, FSM-45PM, and FSM-100P.

The Role of PM Fusion Splicers in Advanced Optical Systems

Unlike standard splicers, PM fusion splicers are designed to splice birefringent fibers used in systems where light polarization must be maintained. Even a small rotational misalignment can disrupt the polarization state and render the fiber unusable in applications such as:

- Coherent optical communications

- Fiber optic gyroscopes

- Optical interferometry

- Quantum communications

- High-power fiber lasers

- Aerospace-grade fiber sensors

This makes axis alignment, arc precision, and mechanical calibration not just important — but mission-critical.

Understanding Each Fujikura PM Splicer Model

Let’s explore the specific features, common issues, and service needs for each of the four major PM splicers from Fujikura.

FSM-20PM – The Pioneer PM Fusion Splicer

Release Era: Early 2000s

Purpose: PM fiber alignment with manual rotation

Key Features:

- Manual rotation stage for fiber alignment

- Single camera axis alignment

- Fusion loss estimation

- Ideal for low-volume R&D labs or legacy systems

Common Issues:

- Manual rotation stage wear or binding

- Camera degradation or misalignment

- Arc instability due to old electrodes

- V-groove contamination

Our Service Focus:

- Clean and lube rotational stages

- Restore camera clarity and replace aged LEDs

- Replace electrodes and recalibrate arc

- Restore functional operation for legacy research tools

FSM-40PM – The Workhorse of PM Splicing

Release Era: Mid-2000s

Purpose: Automated PM fiber splicing with high precision

Key Features:

- Dual-motor axis alignment

- Rotational fiber alignment system

- Touchpad interface

- Basic PER estimation

Common Issues:

- Electrode degradation

- Faulty arc discharge power module

- Axis motor jitter or slippage

- Display interface failure

- Misalignment of core due to axis drift

Our Service Approach:

- Replace motors and recalibrate alignment algorithms

- Reflash firmware and update internal memory

- Rebuild touchscreen control interface

- Clean optical paths and re-zero stage movements

FSM-45PM – Precision with Advanced Features

Release Era: Late 2000s

Purpose: Industrial-grade PM fiber fusion for production

Key Features:

- Motorized fiber rotation (0.01° resolution)

- Dual-camera system (X & Y axes)

- Arc power feedback control

- Better arc optimization for LDF and specialty fiber

- Stored splice programs and memory

Common Failures:

- Axis calibration loss over time

- X or Y camera flicker or failure

- Overheating from high splice frequency

- Firmware lock-up or boot errors

- Misjudged splice loss due to dirty optical elements

Our Advanced Service Options:

- Replace arc power boards and rebuild cooling fans

- Clean and re-center dual cameras

- Perform 50+ test splices on PM and standard fiber

- Calibrate splice memory for fiber-specific profiles

- NIST-traceable arc tuning and PER analysis

FSM-100P – The Flagship for R&D and Advanced Applications

Release Era: 2010s to present

Purpose: High-end research and manufacturing

Key Features:

- Fully automated rotational alignment (core or cladding)

- PANDA fiber alignment support

- Sub-micron stepper motor accuracy

- Built-in extinction ratio estimation

- Modular heater systems

- USB, RS232, and SD card interfaces for data storage

Most Frequent Issues:

- Axis servo drift (rotation and translation)

- Arc instability from software update conflicts

- High-resolution camera malfunction

- Data logging errors (USB/SD card issues)

- PER module malfunction

Our Service Capabilities for FSM-100P:

- Axis re-zeroing using PANDA fiber with dual-view monitoring

- Firmware refresh and software version upgrades

- Camera module replacement with calibration

- High-temperature chamber cleaning

- PER calibration using controlled lab testing

- Replacement of cleaver and heater parts as needed

Aumictech’s PM Splicer Service Workflow

We treat every Fujikura PM splicer — whether legacy or modern — with laboratory-grade care. Our service process includes:

1. Intake & Diagnostic

- Visual inspection, arc count, firmware version logging

- Functional tests of axis movement, arc initiation, and screen response

- Test splices using Fujikura-recommended PM fiber

- Splice loss and PER measurement (if available)

2. Deep Cleaning

- Disassembly of core fiber path components

- Removal of debris, jacket residue, glue, and dust

- Camera lens and V-groove cleaning under scope

- Clamp and electrode housing cleansing

3. Mechanical & Electrical Repair

- Replacing damaged motors, belts, or hinges

- Repair of display units or control boards

- Battery and power circuit diagnostics

- USB and memory card port diagnostics and cleaning

4. Calibration & Alignment

- Axis re-alignment using reference fibers

- Rotation motor recalibration

- Camera X/Y offset tuning

- Electrode replacement and gap setting

- Arc discharge fine-tuning using stepwise voltage control

5. Software Updates & Backup

- Latest firmware installation

- Memory clearing and user program reconfiguration

- Export/import of splice logs

- Debugging software lock or error codes

6. Final Testing & Certification

- Over 30–50 test splices on real PM fiber

- Splice loss, core alignment image, and arc uniformity evaluation

- Certification issued with NIST traceability

- Optional: Extinction Ratio testing using PANDA fiber and external analysis

Why Choose Aumictech?

- 10+ Years of Optical Equipment Expertise

- USA-Based Service Center (Downingtown, PA)

- 3–5 Day Turnaround (Expedited Available)

- Cleanroom-Like Handling & ESD-Safe Procedures

- Extensive Test Logging & NIST Calibration Option

- Worldwide Shipping and Support

We go beyond simple repair: We revive, optimize, and modernize older units for continued use in high-precision environments.

Who We Serve

- University Labs – Quantum, Photonics, Fiber Research

- Optical Sensor Manufacturers

- Telecom OEMs and Contractors

- Defense & Aerospace R&D Teams

- Fiber Optic Production Lines

- Medical & Biofiber Research Groups

Client Feedback

“We had an FSM-45PM that failed during critical laser development testing. Aumictech restored its functionality and calibrated it within 4 days. Huge cost savings vs. replacement.”

— Optical Lab Director, Boston

“Our FSM-100P was showing strange PER drift. Aumictech nailed the issue — it was a tiny X-axis motor slip. They fixed it and calibrated everything, including firmware.”

— Senior Telecom Engineer, Dallas

Contact Aumictech for Service or Support

Got an FSM-20PM, FSM-40PM, FSM-45PM, or FSM-100P that’s underperforming? Don’t retire it — restore it.

Email: sales@aumictech.com

Website: www.aumictech.com

Final Words

Fujikura’s PM fusion splicers are still the gold standard in polarization-maintaining fiber systems. Whether you rely on the rugged FSM-40PM or the cutting-edge FSM-100P, regular service ensures accuracy, compliance, and longevity. At Aumictech, we honor the engineering behind these machines with precision service that helps you get years more from your investment.

Trust us with your fiber’s future — precision is our promise.