In today’s high-precision optical and RF engineering world, the reliability of your test equipment directly determines the reliability of your research, your production lines, and in many cases even the integrity of the data you publish. Laboratories working with fiber-optic communications, semiconductor photonics, DWDM system testing, or advanced photonics R&D rely heavily on two categories of tools:

- Optical Spectrum Analyzers (OSAs) such as Ando AQ6317B, Yokogawa AQ6370D, AQ6319, AQ6150 series, and more

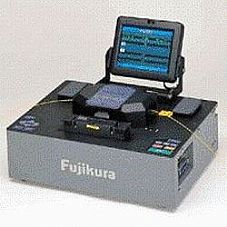

- Fusion Splicers, particularly high-precision polarization-maintaining splicers like Fujikura FSM-20PM, FSM-40PM, FSM-100P, FSM-100M, and the classic single-fiber models

At Aumictech, we’ve observed a consistent pattern across R&D labs, universities, and fiber-optic production facilities:

most labs don’t struggle with using the equipment — they struggle with keeping it calibrated, stable, and performing at factory specifications.

This is where Aumictech steps in.

For years, our engineering team has specialized in deep-level, OEM-style calibration, repair, restoration, and performance tuning of legacy and modern test equipment. And today, we have become one of the fastest-growing calibration partners for labs across the United States, India, Singapore, and the Middle East.

This blog explores in detail how Aumictech supports optical labs with world-class calibration and repair services for Ando/Yokogawa OSAs and Fujikura fusion splicers—and why so many labs now trust us over manufacturer service centers.

Visit us for OSA repairs: Here

Visit us for Fusion splicer repairs: Here

Why OSA Calibration Has Become More Critical Than Ever

Optical Spectrum Analyzers are the backbone of photonics testing. Whether you’re characterizing a DWDM grid, validating laser linewidth, performing OSNR measurements, or analyzing the spectral purity of semiconductor lasers—accuracy is everything.

However, OSAs are also sensitive instruments. Some common issues we see at labs include:

✔ Wavelength drift over long-term usage

Most Ando and Yokogawa OSAs, especially the AQ6317 and early AQ6370 units, slowly drift by 10–80 pm per year. Without regular calibration, channel spacing and OSNR calculations become unreliable.

✔ Degraded internal reference lamps or calibration sources

Older OSAs depend on internal wavelength references (often HeNe or SLED-based). Over time, these degrade or shift.

✔ Slower sweep speeds due to aging optical components

Dust on diffraction gratings, weak mechanical motors, and aged detector arrays cause sweep lag and reduced sensitivity.

✔ Incorrect noise floor measurements

This is especially common when the main optical bench loses alignment or the front-end detector gain stages drift.

✔ Broken or dim LCD displays

Many Ando OSAs from the early 2000s experience backlight failure, inverter board issues, or CCFL aging.

✔ Hard drive failures or corrupted firmware

A very common failure point—especially for labs using AQ6317B, AQ6317C, and AQ6319 models with aging IDE hard drives.

Aumictech has developed specialized in-house procedures, diagnostic software, and precision optical references to restore these units back to manufacturer specifications — often better than OEM turnaround times, and at a fraction of the cost.

How Aumictech Performs OSA Calibration (What Makes Us Different)

Over time, we have refined a calibration methodology that closely mirrors the process used by major OEMs — but with additional steps based on real lab feedback and field failures.

Here’s a glimpse behind the scenes:

1. Multi-Point Wavelength Alignment (Factory Methodology)

Instead of using a single reference laser, we calibrate using multiple wavelength anchors:

- 1310 nm single-frequency reference

- 1490/1550 nm dual-wavelength laser

- 1625 nm tunable reference

- Optional erbium ASE source for noise floor validation

This ensures wavelength accuracy across the entire operational spectrum, not just a single point.

2. Photodetector & Sensitivity Calibration

Using calibrated variable attenuators and power standards, we verify:

- Absolute power accuracy

- Linear dynamic range

- Noise floor sensitivity

- Level offset accuracy

- Sweep repeatability

We also compensate for detector aging using proprietary tuning methods.

3. Grating Motor & Sweep System Optimization

This is the part most service companies skip.

We clean, tune, and re-lubricate the grating motor assembly to restore factory sweep speeds — especially for AQ6317B and earlier units.

4. Optical Bench Cleaning and Alignment

We use a controlled ESD-safe optical environment to clean:

- Diffraction gratings

- Folding mirrors

- Internal waveguide alignment paths

- Input coupling

Lab users often report seeing 2–4 dB improvements in sensitivity after this alone.

5. Firmware & Hard Drive Restoration

For older Ando OSAs, we:

- Clone failing IDE drives

- Replace with SSD equivalents (using converters)

- Repair corrupted calibration files

- Restore missing system utilities

- Rebuild bad sectors

This dramatically extends the life of units that many OEMs consider “obsolete”.

Yokogawa AQ Series Support (AQ6370/AQ6380/AQ6150)

We specialize deeply in AQ series OSAs because these are the most widely used in optical labs today.

Common repairs we perform:

- Replacing failing xenon reference lamps

- Fixing “Wavelength Calibration Error” messages

- Fan/motor replacements for noisy sweep mechanisms

- Replacing cracked front-end connectors

- Repairing broken optical benches from shipping damage

- Restoring dead LCDs or touchscreens

- Fixing power supply whine and failure

- Re-installing firmware after boot loops

We also offer fast-turnaround emergency calibration for labs preparing for audits or certification.

Aumictech’s Expertise in Fujikura PM Splicer Repair and Calibration

Most photonics labs use at least one Fujikura splicer, and many use the high-precision polarization-maintaining models. These are incredibly powerful tools—but also incredibly sensitive.

Common Failures We Repair on Fujikura 20PM, 40PM, and 100P Series

✔ Arc calibration failures

Caused by aged electrodes or mismatched arc profiles.

✔ PM fiber rotational alignment drift

This is the most common issue on PM splicers.

Over time, the fiber rotation motors lose accuracy, causing:

- Poor extinction ratio

- High splice loss

- Unstable alignment during arc fusion

We have custom jigs and software profiles to realign PM axes with micrometer precision.

✔ Z-axis motor failure and contamination

We clean and re-center all axis motion stages while recalibrating speed curves.

✔ Heater tray failures

Old heater units degrade and fail to reach target shrink temperatures. We replace or rebuild these assemblies.

✔ Dust contamination on V-grooves

Even a microscopic dust particle can throw alignment off by several microns.

Our technicians use high-mag inspection tools and alignment microscopes to restore perfect V-groove geometry.

✔ Touchscreen failures

Very common on 40PM and early 100P units. We replace digitizers, LCDs, or full display assemblies.

✔ Arc power drift

We reset:

- Arc current

- Arc duration

- Prefuse current

- Gap offset

- Prefuse stabilization timing

This ensures strong, repeatable splices.

Full Factory-Style Fujikura Splicer Calibration Process at Aumictech

1. Optical Axis Realignment

We use precision PM fiber test samples to re-align rotational axes and fix extinction ratio drop.

2. Electrode Conditioning & Replacement

We inspect under microscope, recondition or replace electrodes, and reset electrode offsets.

3. X/Y/Z Motor Optimization

We recalibrate motor travel, backlash, speed curves, and center offsets.

4. Loss Estimation Re-tuning

Many splicers start giving inaccurate loss values.

We recalibrate the entire loss-estimation algorithm.

5. Heater Tray Temperature Calibration

We use real-time temperature probes to ensure repeatable splice protection.

6. Full Dust & Contamination Cleaning

A full teardown cleaning drastically improves alignment consistency.

Why Labs Prefer Aumictech Over OEM or Other Service Providers

We’ve earned trust because our approach isn’t superficial. It’s built on engineering experience, not just “service scripts”.

✔ Faster Turnaround Times

OEM lead times often exceed 4–8 weeks.

Ours typically range 3–10 business days.

✔ Affordable Pricing

We offer calibration and repair services at below-market prices, especially for local partners, because we believe in building long-term relationships—not one-time invoices.

✔ High-End Test Bench

We operate our own calibrated references, tunable lasers, PM fiber test benches, and RF/optical metrology tools.

✔ We Still Repair “Obsolete” Equipment

Many OEMs stop supporting:

- Ando OSAs

- Early Yokogawa AQ units

- Fujikura PM splicers older than 12 years

We don’t.

✔ Real Engineers, Not Script Followers

Every device that comes in receives a deep technical teardown, not just a canned “cal-check”.

✔ Detailed Reporting

You receive:

- Pre-service diagnostic report

- Calibration test report

- Repair summary

- Parts replaced

- Before/after data (wavelength & power accuracy graphs)

Industries That Rely on Aumictech Today

We serve a wide range of labs and companies, including:

- Semiconductor manufacturing fabs

- Fiber cable production lines

- Telecom carriers

- University photonics labs

- Quantum research facilities

- Biomedical optical imaging groups

- Defense & aerospace photonics programs

- Fiber-optic equipment resellers

- R&D companies developing next-gen photonics

Our calibration standards meet NIST-traceable requirements, making our reports suitable for ISO audits and federal compliance programs.

Why Your Lab Should Work with Aumictech

Whether you’re dealing with wavelength drift in your AQ6317B, a dead touchscreen on your Fujikura 40PM, weak arcs on a 100P, or inconsistent OSNR results on your Yokogawa AQ6370D — Aumictech provides the expertise, affordability, and turnaround speed your lab needs.

We help labs eliminate downtime, avoid expensive OEM quotes, and keep mission-critical photonics research on track.

If your OSA or fusion splicer is showing any of the following:

- Wavelength errors

- Unstable readings

- High splice loss

- Arc calibration failures

- Slow sweeps

- Touchscreen issues

- Boot loop or HDD failure

- Weak detector sensitivity

…then you’re at the right place.

Ready to Calibrate or Repair Your Equipment?

Aumictech is ready to support your lab with unmatched expertise in:

✔ Ando OSAs (AQ6317B/AQ6317C/AQ6319/etc.)

✔ Yokogawa OSA AQ series (AQ6370/AQ6380/AQ6150/etc.)

✔ Fujikura Fusion Splicers (20PM / 40PM / 100P / 100M / Single-Fiber)

Fast turnaround. OEM-level precision. Below-market pricing.

📧 Email: sales@aumictech.com

🌐 Website: https://aumictech.com

📍 Serving USA, Canada, India, Middle East & international labs