Service & Repair of Ericsson FSU 995PM Fusion Splicer

Ericsson FSU 925PM, 975PM & 995PM Fusion Splicer – Professional Repair, Precision Alignment & Full Recalibration

We specialize in repair, maintenance, and calibration services for the Ericsson FSU 925PM, 975PM, and 995PM Fusion Splicers—rugged and highly precise tools widely used in optical fiber network installations, lab environments, and field deployments. Known for their core-to-core alignment precision and long-term durability, these fusion splicers remain in use globally across telecom, aerospace, defense, and broadband infrastructure projects. Whether your splicer is showing arc issues, fiber mismatch, or display failure, our experienced team can restore it to factory-grade functionality with precision alignment and full system verification.

End-to-End Fusion Splicer Service Process

Complete Diagnostic Evaluation

We begin with a thorough inspection and performance test to identify:

Arc quality and arc count accuracy

Fiber core alignment (X/Y/Z axis movement)

Splice loss estimation and repeatability

V-groove cleanliness and tension settings

Display, keypad, and button responsiveness

Battery condition and charge cycles

Internal software/firmware version integrity

We test using single-mode and multimode fiber, simulate field splicing conditions, and inspect all internal systems to identify performance degradation or mechanical wear.

Common Issues We Repair

Misaligned fibers or poor splice quality

High splice loss or failed splice estimation

Worn or misfiring electrodes

Faulty motors (X, Y, Z alignment or fiber feed)

Arc power calibration failure

Dust or damage in V-groove or fiber clamps

Display screen issues (dim, flickering, or cracked LCD)

Keypad or touch control failure

Battery not charging or holding charge

Firmware bugs or boot failure

Precision Mechanical Repair & Cleaning

We perform mechanical adjustments and cleaning, including:

Replacing or reshaping electrodes

Cleaning and adjusting V-grooves, fiber clamps, and lens optics

Re-aligning fiber paths using high-resolution camera feedback

Calibrating arc discharge settings to match fiber type and environmental conditions

Motor & Sensor Testing

Each internal motor (X, Y, Z axis) is tested for travel precision, backlash, and response time. We replace worn actuators and recalibrate their range using OEM procedures.

Display & Interface Repair

We restore or replace display screens and front panel components as needed. All keypads, input buttons, and user interface systems are tested and repaired for full functionality.

Firmware Validation & Functional Tests

Post-repair, the unit is updated to the latest supported firmware (if available) and run through all functional self-tests. Splice loss, arc centering, and heat-shrink operations are validated.

Full Calibration & Verification

Every serviced Ericsson splicer undergoes:

Arc calibration and tuning based on fiber type

Splice loss measurement and repeatability checks

Fiber core alignment calibration using test fibers

Tension testing and mechanical integrity assessment

A final report with splice performance and system diagnostics is included with each unit.

Why Choose Us?

Specialized experience with Ericsson FSU fusion splicer models, including 925PM, 975PM, and 995PM

Deep understanding of fusion arc behavior, mechanical alignment, and optical core matching

Fast turnaround – most repairs completed within 3–5 business days

All services backed by a repair warranty and 15-day Right of Return

Secure worldwide shipping and shock-resistant packaging

Accept multiple payment methods: PayPal, ACH, wire transfer, and credit cards

Ideal for:

Fiber optic installers relying on Ericsson FSU units for daily field operations

Companies needing certified refurbishment before resale or redeployment

R&D labs using core-to-core splicing for testing and prototyping

Telecom operators restoring legacy but highly durable splicing equipment

Get Your Ericsson Fusion Splicer Back to Peak Performance

If your Ericsson FSU 925PM, 975PM, or 995PM Fusion Splicer is underperforming, showing arc issues, or failing to align fibers accurately, we’re here to help. Our advanced diagnostic procedures, OEM-style calibration, and expert repair practices will ensure your unit is ready for precise, low-loss splicing in any application.

Request a quote today to restore your Ericsson fusion splicer to full working condition.

$2,480.00

Professional service and repair for the Ericsson FSU 995PM Fusion Splicer, ensuring optimal performance and reliability for your fiber optic splicing needs.

Agilent 856x series Spectrum Analyzer Extender cable

$365.00York / PK Technology FK12 Angled Fiber Cleaver **CALIBRATED**

$2,630.00Yokogawa WT1600 Digital Power Meter

$3,080.00Yokogawa PZ4000 Power Analyzer

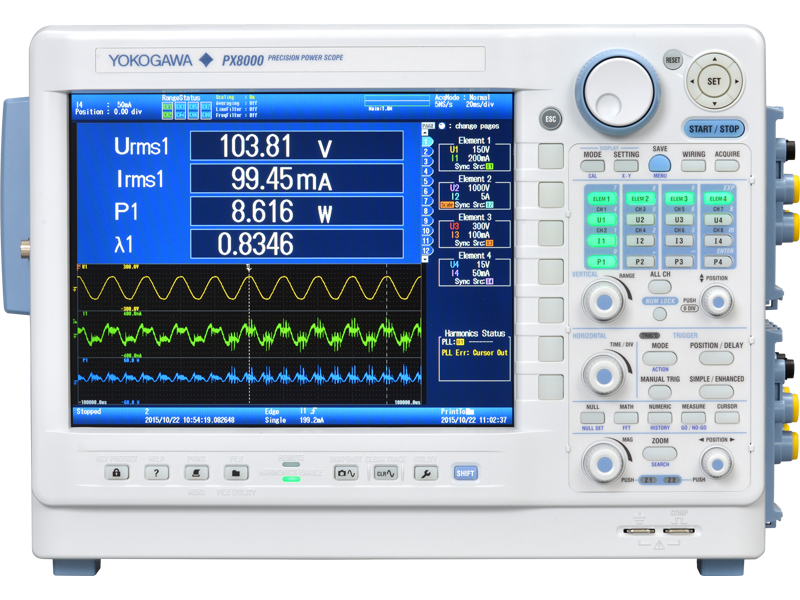

$4,480.00Yokogawa PX8000 Precision Power Scope, 100 MS/s, 20 Hz to 6.4 kHz

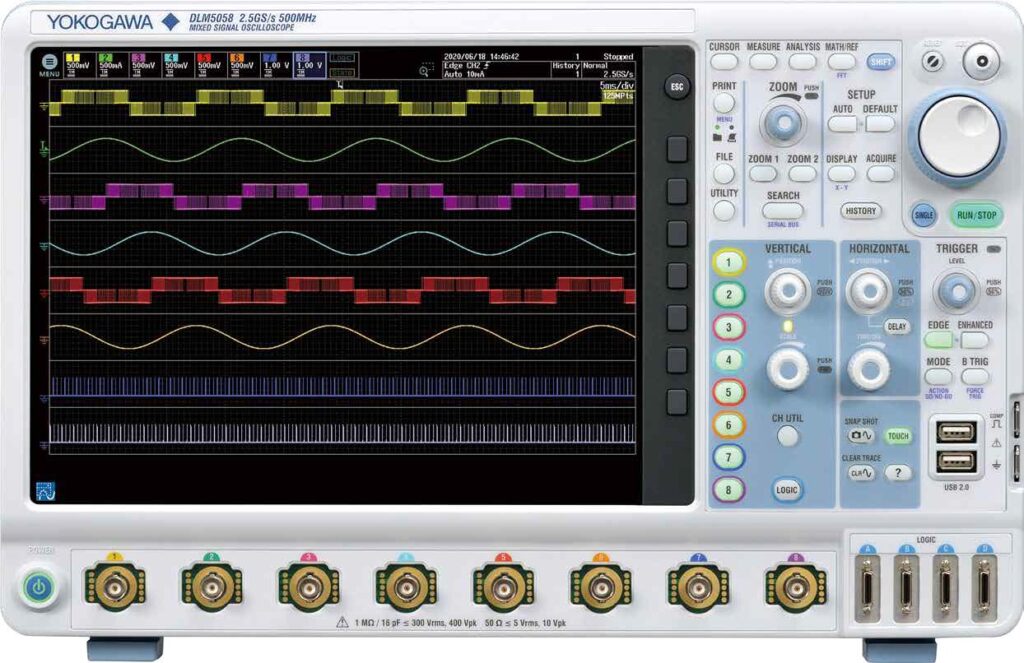

$31,480.00Yokogawa DLM5058 Mixed Signal Oscilloscope: 8-Channel, 500 MHz

$4,250.00Yokogawa DLM5054 Mixed Signal Oscilloscope: 4-Channel, 500 MHz

$4,250.00Yokogawa DLM5038 Mixed Signal Oscilloscope: 8-Channel, 350 MHz

$4,250.00Yokogawa DLM5034 Mixed Signal Oscilloscope: 4-Channel, 350 MHz

$4,550.00Yokogawa DL7200 CAN Bus Signal Analyzer W D,BS,C10

$1,279.00

Calibration Services

Accurate measurements are critical in every lab and manufacturing environment. That’s why we offer NIST-traceable calibration. Using precision standards and certified reference equipment, our team performs a full verification of wavelength accuracy, power levels, and response time. After calibration, your instrument not only meets but often exceeds factory specifications. Every service includes a calibration certificate to support ISO and quality compliance audits.

Industry Applications

Our repair and calibration services are trusted by telecommunications providers, research labs, universities, and manufacturing plants worldwide. By maintaining tight tolerances and providing quick turnaround, Aumictech helps minimize downtime and maximize productivity. Many of our clients rely on us for scheduled preventive maintenance, ensuring instruments remain accurate during critical testing or production runs.

Cost Efficiency & On-Site Options

Unlike OEM services that often come with long lead times and high costs, Aumictech provides affordable repairs with flexible turnaround options. For large facilities or urgent needs, we also offer on-site calibration—bringing our certified equipment directly to your lab or production line. This reduces shipping delays, minimizes handling risks, and keeps your operations running smoothly without interruption.

Why Choose Aumictech

Choosing Aumictech means partnering with a dedicated repair and calibration lab focused on optical and RF test equipment. With decades of combined expertise, an extensive inventory of replacement parts, and specialized tooling for high-end instruments, we deliver reliable service at a fraction of the replacement cost. Our commitment to quality, precision, and fast turnaround makes us the trusted partner for organizations looking to extend the life and accuracy of their critical equipment.