RF Calibration Equipment

Showing 121–132 of 149 results

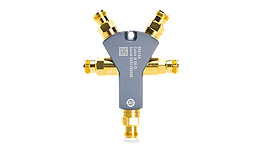

Agilent / Keysight 85519A 4-in-1 OSLT Calibration Kit, DC to 18 GHz, Type-N (f) 50 ohm

$5,147.80Agilent / Keysight 85518A 4-in-1 OSLT Mechanical Calibration Kit, DC to 18 GHz, Type-N (m) 50 ohm

$4,823.80Agilent / Keysight 85058V Verification kit 1.85mm 10 MHz to 67 GHz

$16,251.00Agilent / Keysight 85057B Verification kit 2.4mm 10 MHz to 50 GHz

$12,923.80Agilent / Keysight 85056K Mechanical Calibration Kit, DC to 50 GHz, 2.4 mm & 2.92 mm

$11,303.80Agilent / Keysight 85056D Economy Mechanical Calibration Kit, DC to 50 GHz, 2.4 mm

$7,999.00Agilent / Keysight 85056A Standard Mechanical Calibration Kit, DC to 50 GHz, 2.4 mm

$14,219.80Agilent / Keysight 85054B Standard Mechanical Calibration Kit, DC to 18 GHz, Type-N, 50 ohm

$10,493.80Agilent / Keysight 85053B Verification Kit, 3.5 mm 300 kHz to 26.5 GHz.

$4,345.90Agilent / Keysight 85053A 3.5 MM verification kit

$1,567.60Agilent / Keysight 85052D Economy Mechanical Calibration Kit, DC to 26.5 GHz, 3.5 mm

$7,091.80Agilent / Keysight 85052C Precision Mechanical Calibration Kit, DC to 26.5 GHz, 3.5 mm

$628.00

RF Calibration Equipment

RF calibration equipment is used to establish confidence in radio frequency measurements by verifying, adjusting, and maintaining the accuracy of RF test systems. In professional RF environments, calibration is not optional. It is the foundation that ensures every measurement, comparison, and compliance decision is based on traceable and repeatable data. At Aumictech, RF calibration equipment is treated as a critical layer of the RF workflow, not a secondary accessory.

RF systems drift over time due to component aging, thermal cycling, and environmental exposure. Without proper calibration, even high-end instruments can produce misleading results. RF calibration equipment provides known reference standards that allow engineers and technicians to validate system performance, correct deviations, and maintain measurement integrity across the entire frequency range.

Purpose of RF Calibration in Real-World RF Systems

RF calibration equipment is used to characterize signal paths, validate instrument accuracy, and remove systematic errors from RF measurements. In laboratory environments, calibration establishes a reliable baseline for research and development work. In production and manufacturing, it ensures consistent test results across multiple stations and production cycles.

Calibration equipment is also essential in compliance testing, where regulatory limits are enforced based on precise RF measurements. In these applications, traceability and repeatability are just as important as raw instrument performance. Calibration ensures that measured power levels, frequency accuracy, modulation quality, and noise performance reflect true system behavior.

Core Measurement Parameters Addressed by RF Calibration

RF calibration equipment supports the verification of multiple critical parameters. Power calibration confirms that signal generators, power sensors, and analyzers are producing and measuring correct signal levels. Frequency calibration ensures oscillators, synthesizers, and reference clocks remain aligned with accepted standards.

Amplitude flatness calibration validates consistent response across frequency, which is especially important for wideband systems. Phase and time alignment calibration supports accurate vector measurements, modulation analysis, and network characterization. Noise performance calibration helps identify sensitivity limits and validate receiver front-end behavior.

Each of these parameters directly affects system accuracy, and errors in any one area can propagate throughout the RF signal chain.

Types of RF Calibration Equipment

RF calibration equipment includes reference signal sources, power standards, attenuation standards, and impedance standards. These devices provide known, stable reference points that can be used to validate RF instruments and systems.

Calibration kits are commonly used with network analyzers to establish accurate reference planes for reflection and transmission measurements. These kits include precision standards that define known impedance conditions across frequency.

Reference power sources and calibration sensors are used to verify output levels and measurement accuracy in RF power measurement systems. Step attenuators and fixed standards support amplitude verification and linearity checks.

Advanced calibration systems may integrate multiple reference elements into automated workflows, allowing repeatable and documented calibration across complex RF test setups.

Design and Stability Considerations

RF calibration equipment is designed with long-term stability as a primary objective. Materials, internal construction, and environmental shielding are selected to minimize drift over time. Temperature stability is especially critical, as small thermal variations can significantly affect RF reference accuracy.

Mechanical precision also plays a key role. Connectors, interfaces, and internal geometries must maintain consistent electrical characteristics across repeated connections and extended use. High-quality calibration equipment is built to withstand frequent handling without degradation in performance.

Traceability to recognized standards is essential in professional calibration environments. Calibration equipment used in regulated or audited settings must support documented verification paths and consistent performance history.

Where RF Calibration Equipment Is Used

RF calibration equipment is used in research laboratories, production test floors, calibration labs, and field service environments. Telecommunications providers rely on calibration to maintain network performance. Aerospace and defense programs require calibration to ensure mission-critical RF systems perform as designed.

Semiconductor manufacturers use RF calibration equipment during device characterization and high-volume testing. Universities and research institutions depend on calibrated systems to ensure experimental validity and repeatable results.

In service and maintenance operations, calibration equipment supports periodic verification of RF instruments to ensure continued compliance and reliability.

Selecting RF Calibration Equipment

Choosing RF calibration equipment requires an understanding of frequency coverage, required accuracy, environmental conditions, and integration with existing RF systems. The equipment must align with the performance level of the instruments being calibrated and support the specific measurement parameters involved.

At Aumictech, RF calibration equipment is selected and supported with practical application knowledge, ensuring it meets the needs of advanced RF testing, calibration, and verification workflows. The focus is on reliability, stability, and confidence in every RF measurement.