Sensors & Transducers

Showing 13–24 of 106 results

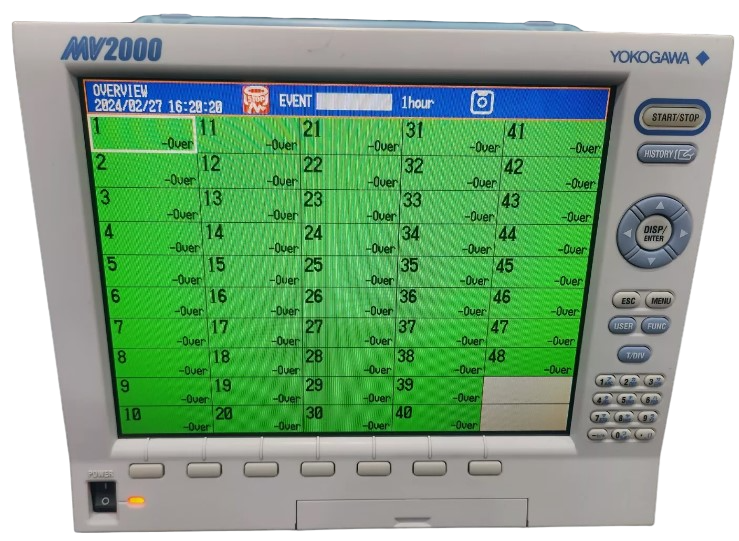

Yokogawa MV2030 Portable Paperless Recorder, 30 Ch, 1 S (Fast sampling mode: 125 ms)

$4,480.00

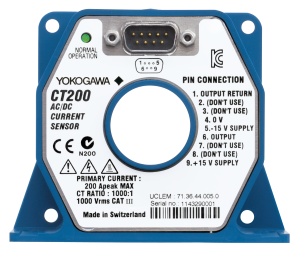

Yokogawa CT2000A AC/DC Current Sensor

$0.00Yokogawa CT200 AC/DC Current Sensor

$1,650.00

Yokogawa CT1000A AC/DC Current Sensor

$2,479.00

Yokogawa CT1000 AC/DC Current Sensor

$2,070.00

Tektronix 80C11B optical sampling oscilloscope

$45,880.00

Starrett 752A-12 Pro Site Protractor

$230.00

Newport 850G – Motorized Linear Actuator, ESP-Compatible, 2″ Travel Range

$0.00ILX Lightwave OMH-6735B – InGaAs Wavehead

$0.00HP / Agilent 5180A Waveform Recorder

$466.00Fujikura FPM-05PG Sensing Element/Gauge

$19.00Anritsu MA24002A Thermal Sensor, 10 MHz to 18 GHz

$1,230.00

Sensors & Transducers

Sensors and transducers are fundamental components used to detect, measure, and convert physical phenomena into usable electrical signals. They form the interface between the real world and electronic systems, enabling accurate monitoring, control, and analysis across a wide range of applications. At Aumictech, sensors and transducers are treated as precision measurement elements, because the quality of the sensing interface directly determines system accuracy and reliability.

In professional test, industrial, and RF environments, sensors and transducers are not generic parts. They are carefully selected devices designed to operate within defined ranges, environmental conditions, and accuracy requirements. Small errors or instability at the sensing stage can propagate through an entire system and lead to incorrect decisions, failed tests, or unreliable operation.

Role of Sensors and Transducers in Measurement Systems

Sensors detect physical quantities such as temperature, pressure, force, motion, light, electrical fields, or RF energy. Transducers convert those detected quantities into electrical signals that can be measured, processed, or controlled by instrumentation and control systems.

In test and measurement environments, sensors and transducers enable direct observation of system behavior under real operating conditions. In industrial systems, they provide feedback for control loops, safety systems, and process optimization. In RF and electronic systems, they support power monitoring, signal detection, environmental compensation, and system diagnostics.

Together, sensors and transducers allow engineers to bridge the gap between physical behavior and electronic analysis.

Key Performance Characteristics

Accuracy defines how closely the sensor or transducer output represents the true physical quantity being measured. High accuracy is critical in calibration, validation, and compliance-driven environments.

Sensitivity determines the smallest change that can be detected reliably. High sensitivity is important for low-level signal detection and fine-grained measurement tasks.

Stability affects how consistently the device performs over time and under changing environmental conditions. Drift can lead to measurement errors if not properly managed.

Linearity describes how proportional the output signal is to the input stimulus. Nonlinear behavior can complicate measurement interpretation and calibration.

Response time determines how quickly the device reacts to changes in the measured quantity. Fast response is essential in dynamic systems and automated test setups.

Environmental tolerance defines how well the device performs under temperature variation, vibration, humidity, or electromagnetic interference.

Types of Sensors and Transducers

Electrical and RF sensors are used to measure voltage, current, power, frequency, and electromagnetic fields.

Temperature sensors and transducers monitor thermal conditions in electronic systems, industrial processes, and environmental testing.

Pressure and force transducers convert mechanical stress into electrical signals for structural monitoring, manufacturing, and automation systems.

Optical sensors detect light intensity, wavelength, or position and are used in optical testing, alignment, and inspection systems.

Motion and position sensors measure displacement, speed, and acceleration in control systems and mechanical testing environments.

Specialized transducers are designed for niche applications requiring specific accuracy, frequency response, or environmental performance.

Design and Reliability Considerations

Sensors and transducers are designed with careful attention to materials, internal structure, and signal conditioning to ensure stable and predictable performance. Mechanical construction affects durability and repeatability, especially in high-cycle or harsh environments.

Thermal behavior is a key consideration, as temperature changes can affect sensitivity, offset, and noise characteristics. High-quality devices incorporate compensation techniques to minimize these effects.

Electrical shielding and isolation help protect sensor outputs from noise and interference, which is especially important in RF and high-speed electronic systems.

Connector quality and mounting methods also influence performance, particularly in applications requiring repeated installation or calibration.

Applications Across Industries

Sensors and transducers are used across telecommunications, aerospace and defense, semiconductor manufacturing, industrial automation, and research laboratories. They support equipment testing, system monitoring, environmental control, and performance validation.

Calibration laboratories rely on stable sensors and transducers to establish reference measurements and maintain traceability. Production environments use them to ensure consistency and quality across manufactured products.

Field engineers depend on sensors and transducers for real-time monitoring, diagnostics, and system verification in deployed systems.