Temperature Test Equipment

Showing 1–12 of 31 results

Keithley 740 System Scanning Thermometer

$570.00

Stanford Research Systems SR630 16-Channel Thermocouple Reader

$679.00

Newport HHCT-3 – Thermocouple Calibrator Thermometer

$0.00Hart Scientific Fluke 1524 Reference Thermometer (Temperature Measurement)

$3,050.00Fluke Hart Scientific 1590 Super Thermometer II

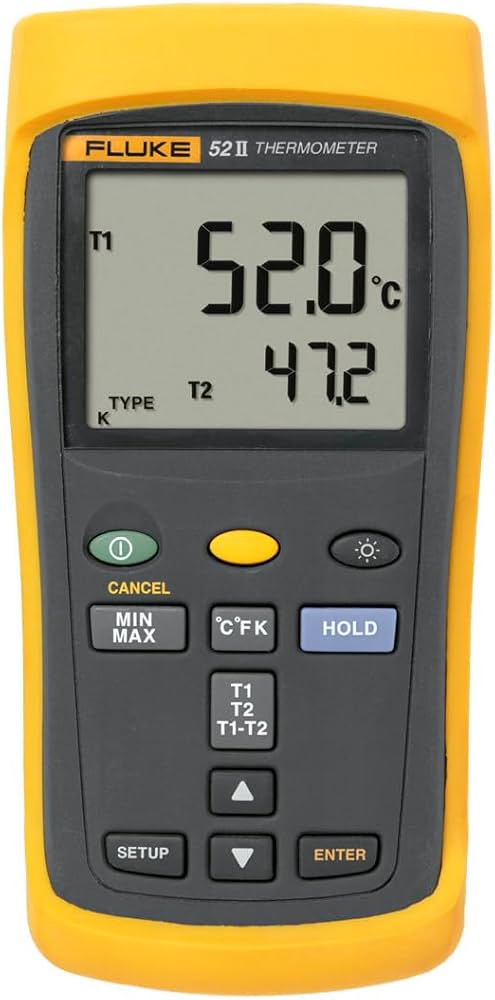

$2,279.00Fluke 52 Digital Thermometer

$679.00Fluke 50D Thermometer

$100.00Fluke / Hart Scientific 1529-R Chub-E4 Thermometer

$6,960.00

ThorLabs TED8080 PRO8 TEC Controller Card, ±8 A, 64 W, Thermistor/IC-Sensor, 2 Slots

$709.00

Teradyne / LitePoint / ZTEC Instruments ZT450PXI-21 8-Bit Digital Storage Oscilloscope

$0.00

Tek-Temp LK-10/NHR/VA/R1

$0.00

Solid State Cooling Systems UC170

$0.00

Temperature Test Equipment

Temperature test equipment is used to measure, control, and simulate thermal conditions to evaluate how devices, materials, and systems perform across defined temperature ranges. In professional testing environments, temperature is one of the most influential variables affecting reliability, accuracy, and long-term performance. At Aumictech, temperature test equipment is treated as a core validation tool, because thermal behavior often determines whether a product succeeds or fails in real-world operation.

Electronic components, RF systems, mechanical assemblies, and materials all respond differently to temperature changes. Without controlled thermal testing, performance data gathered under ideal conditions can be misleading. Temperature test equipment allows engineers to expose systems to realistic operating extremes and verify stability, repeatability, and safety.

Role of Temperature Test Equipment in Testing and Validation

Temperature test equipment is used to subject devices to controlled heating and cooling cycles while monitoring performance and behavior. This allows engineers to identify thermal drift, expansion effects, material fatigue, and failure points.

In electronics and RF testing, temperature affects frequency stability, noise performance, gain, and timing behavior. In mechanical and industrial systems, it influences tolerances, lubrication behavior, and structural integrity.

Temperature testing is also a critical part of qualification, reliability testing, and compliance validation, ensuring products can operate safely and predictably across their specified environmental range.

Key Performance Characteristics

Temperature range defines the minimum and maximum conditions the equipment can achieve. Wider ranges allow testing under extreme operating and storage conditions.

Stability determines how consistently the equipment can maintain a set temperature over time. Stable temperature control is essential for accurate measurement and repeatable test results.

Uniformity affects how evenly temperature is distributed across the test area. Poor uniformity can lead to inconsistent results and misleading conclusions.

Ramp rate defines how quickly temperature can change. Controlled ramping is important for thermal cycling, stress testing, and avoiding damage to sensitive devices.

Accuracy and resolution determine how precisely temperature can be measured and controlled. High accuracy is especially important in calibration and validation environments.

Control and monitoring capability influence how effectively temperature profiles can be programmed, logged, and integrated into automated test workflows.

Types of Temperature Test Equipment

Temperature chambers are used to expose devices to controlled hot and cold environments for environmental and stress testing.

Thermal cyclers support repeated heating and cooling cycles to evaluate fatigue, aging, and long-term reliability.

Temperature controllers regulate heating and cooling elements in custom test setups and production systems.

Thermal plates and hot plates provide localized temperature control for component-level testing and calibration.

Infrared temperature measurement equipment supports non-contact thermal analysis and diagnostics.

Specialized temperature test systems are designed for specific applications requiring precise control, rapid transitions, or compact form factors.

Design and Reliability Considerations

Temperature test equipment is designed with careful attention to insulation, airflow, heating and cooling elements, and sensor placement. These factors directly influence stability, uniformity, and responsiveness.

Sensor accuracy and placement are critical, as temperature readings guide control behavior and data interpretation.

Thermal stress on internal components must be managed to ensure long-term reliability, especially in systems operating at extreme temperatures or high cycle counts.

User interface design and control software play a key role in defining test profiles, monitoring conditions, and documenting results.

Applications Across Industries

Temperature test equipment is used across electronics manufacturing, aerospace and defense, automotive testing, semiconductor fabrication, and research laboratories. It supports component qualification, system validation, and reliability testing.

Calibration laboratories rely on temperature-controlled environments to ensure measurement accuracy and traceability.

Production environments use temperature testing to screen for defects, verify performance margins, and ensure consistency across manufactured products.

Field and service engineers use portable temperature test equipment for diagnostics, troubleshooting, and on-site validation.