Wavelength Meters

Showing 1–12 of 52 results

WR137 Flexible Waveguide 30 in, 6.425-7.125 GHz

$255.00Keysight (Agilent) N2756A MSO Cable Kit, 16-Channel

$0.00Burleigh WA-7600 Multi-Line Wavemeter w calibration

$9,430.00Burleigh WA-7100 Multi-Line Wave meter with calibration

$6,430.00Burleigh WA-1100 Optical Wavelength Meter

$5,430.00Agilent / HP 86122A options ,022 or 021, 400 Wavelength Meter

$9,730.00Agilent / Hp 86120C Multi-Wavelength Meter, 1270 nm to 1650 nm **CALIBRATED**

$7,430.00Advantest TQ8325 Digital Optical Wavelength Meter / UPDATED CALIBRATION

$2,805.00Exfo WA-1500 Laser Wavelength Meter

$10,650.00EXFO / Burleigh WA-1150 Optical Wavelength Meter

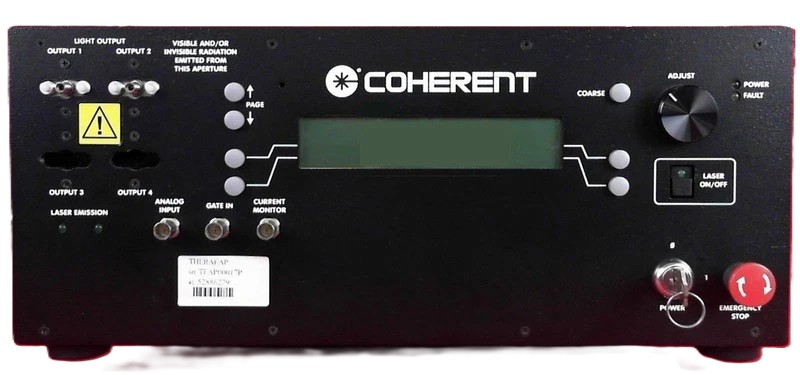

$10,970.00Coherent THERAFAP

$0.00Burleigh WA-7000C Multi Wavelength Meter

$9,330.00

Wavelength Meters

Wavelength meters are precision optical measurement instruments used to accurately determine the absolute wavelength or frequency of laser sources. They play a critical role in optical testing, calibration, and system validation where even small wavelength deviations can lead to significant performance issues. At Aumictech, wavelength meters are treated as reference-grade instruments, because accurate wavelength measurement underpins confidence in optical system performance.

In modern photonic and fiber-optic systems, wavelength accuracy directly affects channel alignment, signal integrity, and system interoperability. Wavelength meters provide the measurement certainty required to develop, test, and maintain these systems across laboratory, production, and field environments.

Role of Wavelength Meters in Optical Systems

Wavelength meters are used to verify and monitor the output wavelength of laser sources, including tunable lasers, fixed-wavelength lasers, and modulated optical sources. They allow engineers to confirm that lasers are operating at the intended wavelength and remain stable over time.

In fiber-optic communication systems, wavelength meters are essential for validating channel spacing and alignment in dense wavelength-division multiplexing environments. In research and development, they support experiments where precise wavelength control is required to study optical phenomena or material behavior.

Wavelength meters are also widely used in calibration workflows to establish traceable wavelength references and validate optical instruments.

Key Performance Characteristics

Measurement accuracy defines how closely the measured wavelength matches the true optical wavelength. High accuracy is critical for channel-specific testing and calibration.

Resolution determines the smallest wavelength change that can be detected. Fine resolution is essential for monitoring drift and tuning behavior.

Repeatability affects how consistently the same wavelength is measured under identical conditions. Reliable repeatability ensures confidence in long-term monitoring and validation.

Measurement speed influences how quickly wavelength data can be acquired. Fast measurement is important for dynamic systems and automated test environments.

Wavelength range defines the spectral coverage of the instrument. Broad coverage supports testing across multiple optical bands.

Stability over time and temperature ensures that the wavelength meter itself does not introduce measurement uncertainty.

Types of Wavelength Meters

Interferometer-based wavelength meters provide high accuracy and are commonly used in laboratory and calibration environments.

Diffraction grating-based wavelength meters offer wide wavelength coverage and fast measurement speeds.

High-resolution wavelength meters are optimized for applications requiring ultra-fine wavelength discrimination.

Compact and portable wavelength meters support production testing and field verification.

Multi-channel wavelength meters enable simultaneous measurement of multiple optical sources.

Design and Measurement Considerations

Wavelength meters are designed with precise optical paths and stable internal references to ensure accurate measurements. Mechanical stability and temperature control play an important role in maintaining performance.

Optical input handling is critical, as signal quality, polarization, and power level can influence measurement accuracy. Proper coupling and connector cleanliness are essential for reliable results.

Calibration and traceability are key considerations, especially in regulated or audited environments where documented accuracy is required.

Control interfaces and data output options influence how easily wavelength meters can be integrated into automated test systems and data logging workflows.

Applications Across Industries

Wavelength meters are used across fiber-optic telecommunications, photonics research, semiconductor manufacturing, and optical component testing. They support laser characterization, DWDM and CWDM system validation, and optical sensor development.

Calibration laboratories rely on wavelength meters to establish and maintain wavelength standards. Production environments use them to verify laser output consistency and screen for drift or defects.

Research institutions depend on wavelength meters for experimental validation, spectroscopy, and advanced optical system development.